-

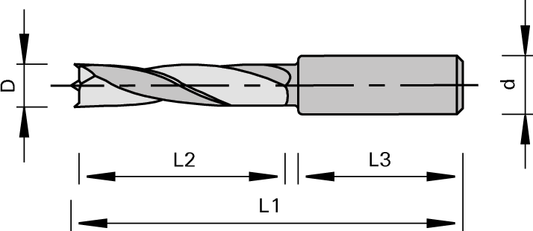

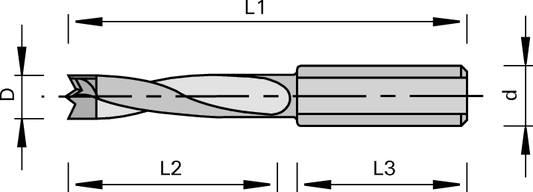

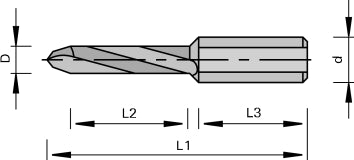

Tungsten Carbide 4 Flute 70mm Brad Point Drill Bit

Regular price From $18.23 USDRegular price -

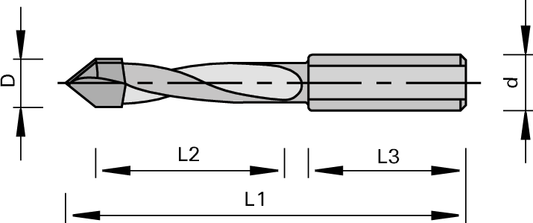

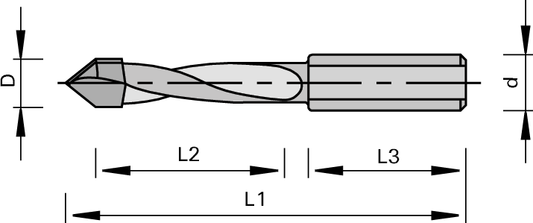

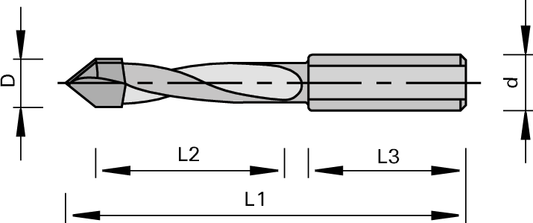

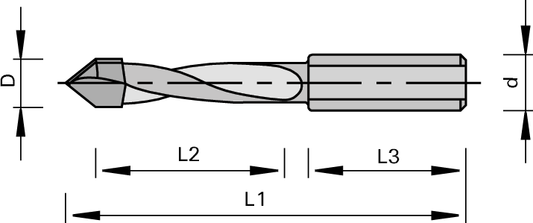

Tungsten Carbide 4 Flute 70mm V-Point Drill Bit

Regular price From $23.41 USDRegular price -

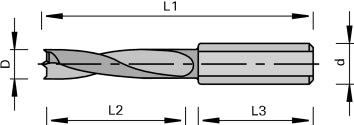

Tungsten Carbide 4 Flute 57.5mm Brad Point Drill Bit

Regular price From $16.50 USDRegular price -

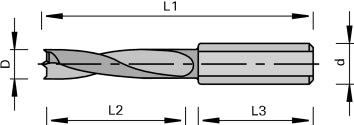

Solid Tungsten Carbide 2 Flute 5x10x30x70mm Mosquito Dowel Bit

Regular price $41.31 USDRegular price -

Solid Tungsten Carbide 2 Flute 5x10x35x70mm Mosquito Through-Hole Bit

Regular price $50.40 USDRegular price -

Tungsten Carbide 2 Flute 70mm Hinge Boring Drill Bit

Regular price From $26.89 USDRegular price -

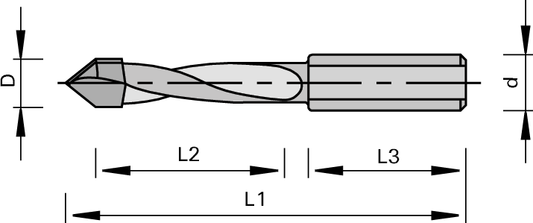

Tungsten Carbide Tipped 2 Flute 70mm Mosquito Dowel Bit

Regular price From $30.65 USDRegular price -

Tungsten Carbide 2 Flute 70mm Cylinder Head Drill Bit

Regular price From $89.90 USDRegular price -

Solid Tungsten Carbide 2 Flute 8x10x35x70mm Mosquito Dowel Bit

Regular price $81.63 USDRegular price -

Solid Tungsten Carbide 2 Flute 8x10x35x70mm Mosquito Through-Hole Bit

Regular price $89.89 USDRegular price -

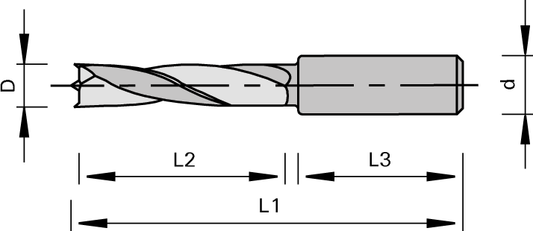

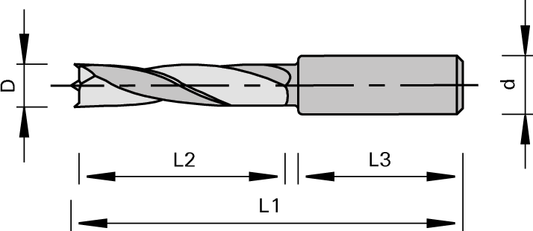

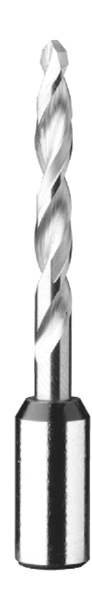

Solid Tungsten Carbide 2 Flute 70mm Mosquito Dowel Bit

Regular price From $39.15 USDRegular price -

Solid Tungsten Carbide 2 Flute 100mm Mosquito Through-Hole Bit

Regular price $66.96 USDRegular price -

Tungsten Carbide 2 Flute 70mm Mosquito Through-Hole Bit

Regular price From $45.84 USDRegular price -

Solid Tungsten Carbide 2 Flute 57.5mm Mosquito Dowel Bit

Regular price From $35.00 USDRegular price -

Tungsten Carbide 2 Flute 57.5mm Mosquito Through-Hole Bit

Regular price $43.97 USDRegular price -

Tungsten Carbide Tipped 2 Flute 57.5mm Mosquito Dowel Bit

Regular price From $29.22 USDRegular price

What is a Boring Machine?

The drills and drilling options LEUCO offers have expanded as the materials in applications have evolved through the years. LEUCO has six drill programs to optimize the tool to the customer's requirements.

- Economy drills

- Standard drills

- Mosquito carbide tipped drills (Mid -high performance)

- Mosquito solid carbide drills (Mid -high performance)

- Topline drills (high-end performance)

- High-Performance drills to obtain a hole quality unsurpassed in the marketplace.

(Drills are also available in high-speed steel typically used to drill small diameters like pilot holes.)

Machines that drill holes are commonly referred to as boring machines. Common types of boring machine applications are

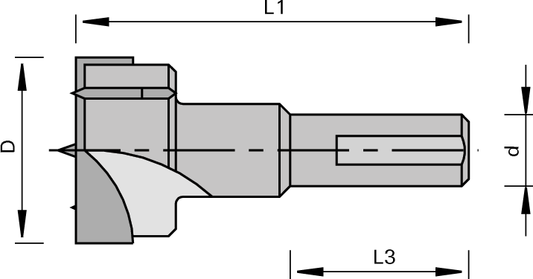

- Hinge boring; for drilling of the hinge cup as well as the hardware mounting holes

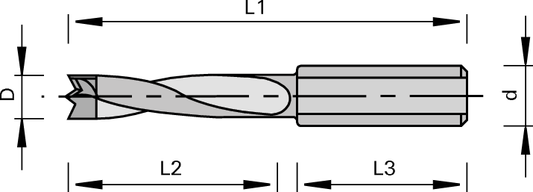

- Dowel drilling; in the panel edge and surfaces for construction holes

- Surface and though hole drilling for shelf pins and other fittings

Machines are available to drill rows of holes simultaneously into the panel surface, as in the case of shelf pins. The individual drills mount into separate drill spindles or chucks. These individual drill spindles occupy a gearbox, commonly referred to as a boring block or drill head. Multiple boring blocks or drill heads can be driven by motors and positioned in a line to drill a virtually limitless number of holes all at one time. In addition to hinge and dowel drilling, machines are also available to drill for hardware.

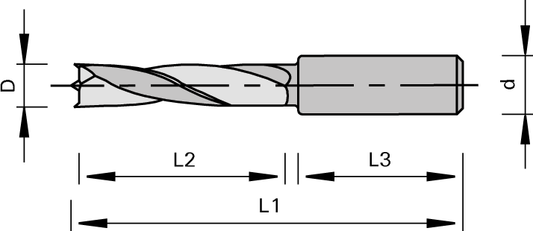

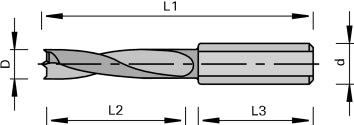

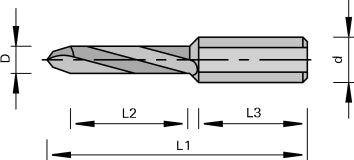

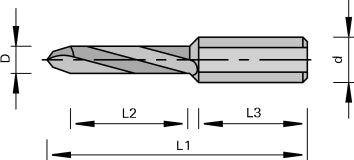

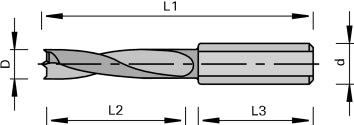

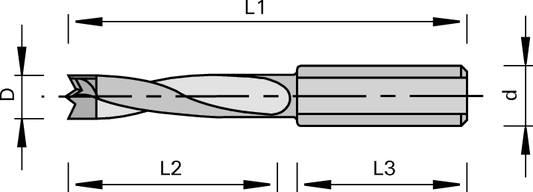

The most common drill tip configurations are

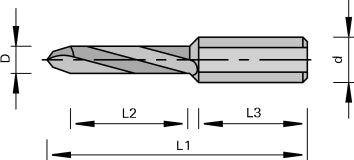

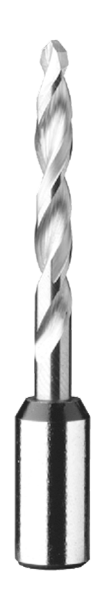

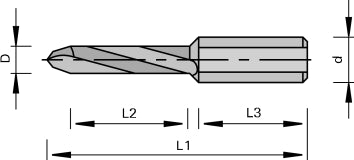

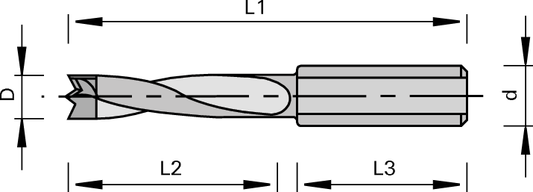

- Brad-point/dowel drill

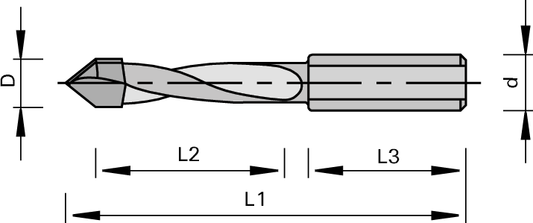

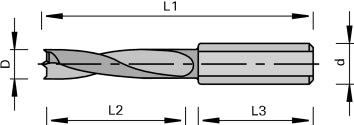

- Through-hole/v-point

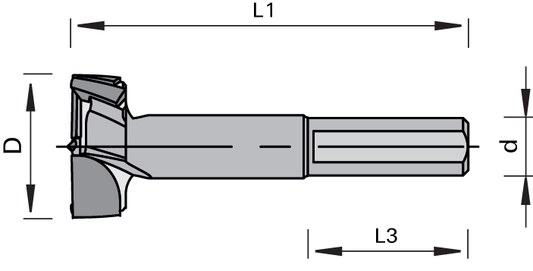

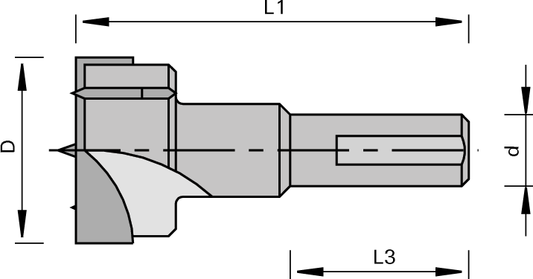

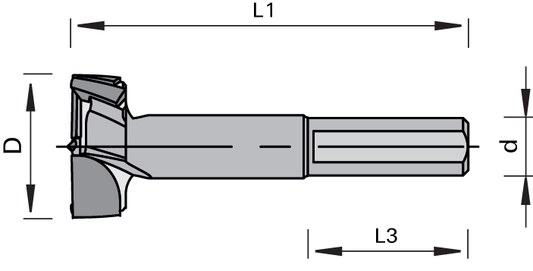

- Cylinder/hinge drills