-

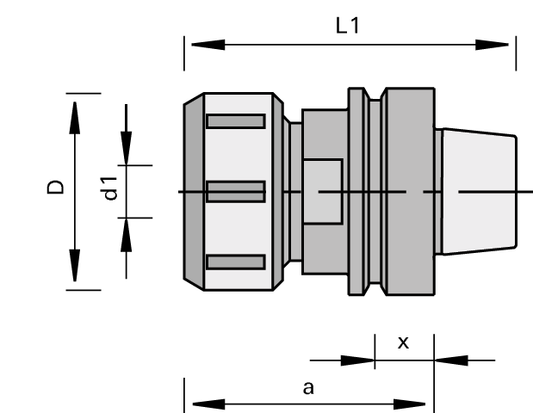

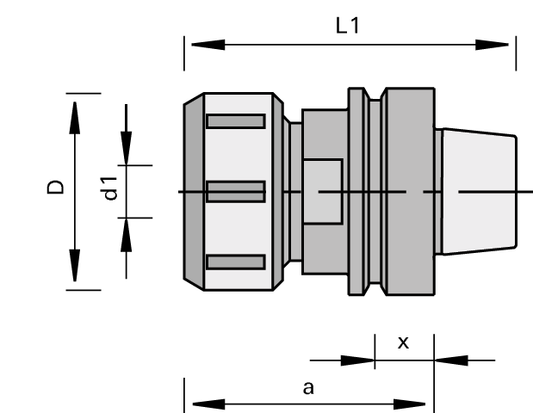

CNC Draw-In Collet Chucks With HSK Shank

Regular price From $306.15 USDRegular price -

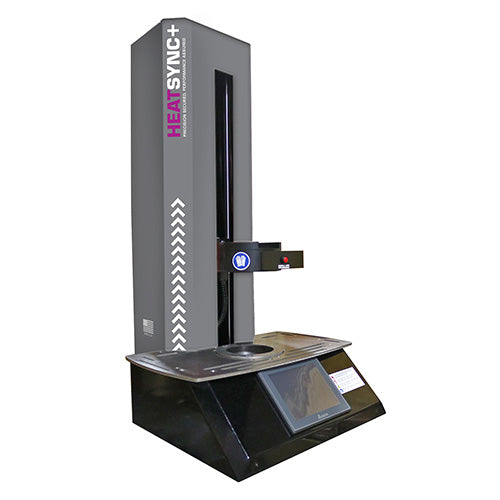

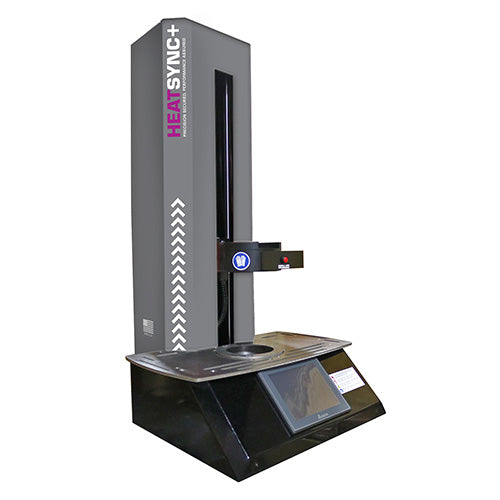

HeatSync+ Induction Unit

Regular price $12,285.00 USDRegular price -

HeatSync Tabletop Induction Unit

Regular price $8,343.00 USDRegular price -

HeatSync Cooler Unit

Regular price $3,483.00 USDRegular price -

CNC SINO Chucks With HSK-Shank

Regular price $934.61 USDRegular price -

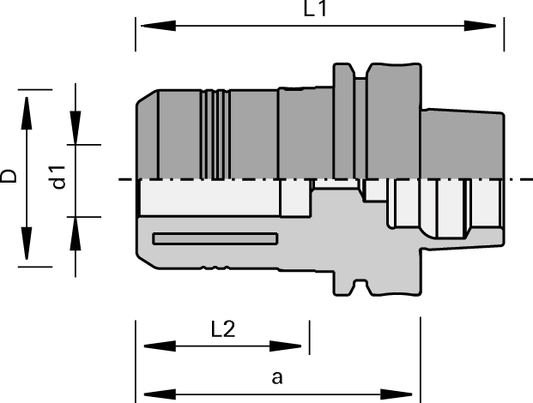

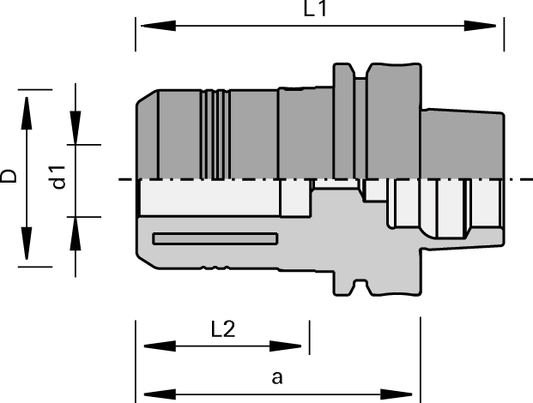

Hydro Clamping Chucks PS-System With HSK 63F Shank

Regular price From $922.26 USDRegular price -

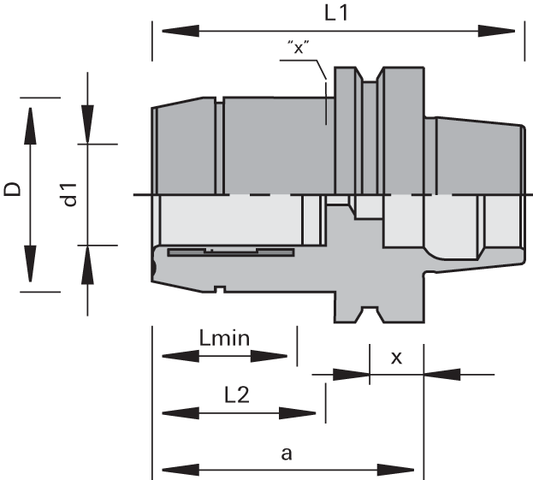

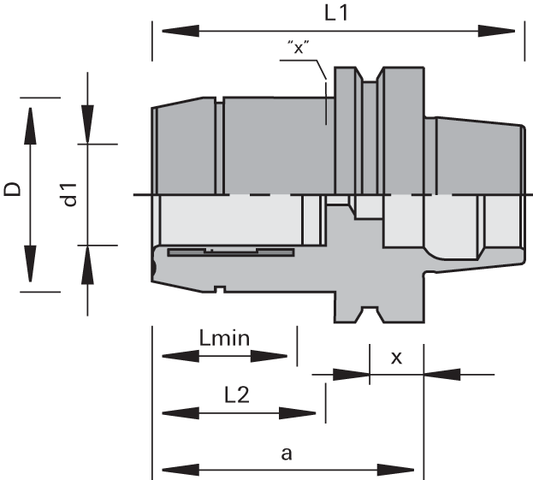

CNC HeatSync Tool Holders

Regular price From $299.81 USDRegular price

LEUCO offers the wide variety of clamping systems for stationary and through-feed manufacturing that ranges from conventional design to closed hydraulic systems.

A tool can never run better than the machine it's running on and the clamping system that fastens it to the machine. The clamping system is the link between the machine and the cutting tool. The better the clamping system, the better the tools cut quality, and edge life. However, the most popular clamping system used today is not necessarily the best option. Collet chucks are by far the industry standard but there are some pretty strong arguments for more accurate systems.

LEUCO Collet Chucks

Very universal and an excellent choice for your odd size, low volume, carbide cylindrical shank type tooling. For best use on CNC machining centers with or without automatic tool changer. Available for right- and left-hand rotation and offers precise clamping for cylindrical shank type tools.

LEUCO PS-System HydroChucks

Internal hydraulics are activated or deactivated by turning a T-wrench. These chucks are considerably more accurate and there is no need to keep track of collet life. Units are available for 1/2”, 3/8” and 25mm shank tools. Optimum clamping choice for diamond tooling. For best use on CNC machining centers with or without automatic tool changers. Available for right- and left-hand rotation and offers precise clamping for cylindrical shank type tools.

The LEUCO Heat Shrink Chuck

The principle is to heat the holder until it expands and then insert the tool. Very large users can justify the heat induction unit for changing tools, but we have a suggestion for all customers. This is the most accurate and most reliable unit. New diamond tooling should be ordered and delivered with a heat shrink holder already installed. The holder is mounted and after sharpening it becomes one unit. In other words, a monolithic design. No unwanted run-out between holder and tool. The holder remains with the tool through its serviceable life. At the end of the tools life the holder can be re-used in another new tool. This is by far the most economical and most accurate, fail-safe clamping mechanism when combined with diamond and insert knife tooling. For best use on CNC machining centers with or without automatic tool changers. Available for right- and left-hand rotation and offer precise clamping for cylindrical shank type tools.

Currently LEUCO offers programs where our heat shrink holders can be added to new as well as existing diamond tools from all manufacturers.

SINO Expansion Toolholders

A polymer contraction, universal toolholder for all-around use on the basis of expansion technology. In terms of quality and versatility, SINO expansion toolholders are especially strong when compared to conventionally used toolholders such as collet chucks. SINO is ideally suitable for large industrial cutting. Benefits of SINO include: optimum ratio between clamping force, rigidity, and damping, easy tool change resulting in long edge-life and low vibration, and versatile clamping range thanks to intermediate sleeves for odd size shanks. When clamped, SINO transfers clamping torque of up to 800 Nm. For best use on CNC machining centers with or without automatic tool changers. Available for right- and left-hand rotation and offer precise clamping for cylindrical shank type tools.

Dust Extraction

Hydro dust extraction system that promotes fast and efficient removal of cutting chips or wood dust in CNC milling operations for grooving, rabbeting and dividing cuts. Particularly suitable for Nesting/Nested-base operations on wood composite panels, with our without laminate, such as particle board and MDF. This system guarantees excellent cut quality, a reduction in heat when cutting resulting in longer tool life, as well as providing a healthier and cleaner work environment. Suitable for CNC machines. Light alloy suction height adjustable turbine fan is delivered mounted on hydro tool holder. This assures higher concentricity of the tool for better finishing. Minimization of setup-times thanks to a dust free work environment.