Translation missing: en.sections.post_template.title: LEUCO Plastics Processing

The Plastic Processing System You Just Can’t Live Without

As an experienced manufacturer in today’s market, you know the importance of being able to cut plastics with the same precision, accuracy, and quality that you cut your other materials. Because this takes specially engineered equipment, the newest sizing saw blades from LEUCO are made to ensure the utmost in excellent cutting quality for plastic materials.

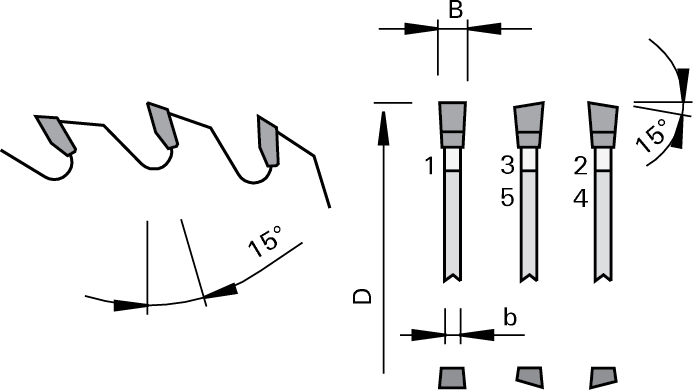

These blades minimize cutting marks and eliminate the need for reworking visible edges. The tooth geometry is specifically designed for a variety of plastic materials, but especially thermoplastics, PMMA panels, polycarbonate panels, abrasive thermosets, anti-fingerprint plastics, and conventional plastics.

With a close tooth pitch, thin plastic panels can be processed without noticeable marks. The LEUCO Plastics Processing System is available only in topline quality, offering the highest performance level with precise run-out and concentricity tolerances. The LowNoise blade option reduces vibration and auxiliary noise during sawing, benefiting machine operators.

- Minimize Cutting Marks

- Eliminate Reworking Edges

- Precision Run-Out

- Low Noise Options

- Expansion Slots Available

- Versatile Compatibility

TOOLING SOLUTIONS THAT WON'T DISAPPOINT

With multiple circular saw blades engineered for cutting plastics with table saws, vertical panel sizing saws and clipping and miter saws, LEUCO can help you overcome challenges that arise from the growing use of plastics in furniture and kitchens applications. These plastics can have widely different characteristics from each other. For instance, thermoplastics such as polycarbonate and polystyrene easily become too warm and melt when sawed, while thermosets tend to chip.

These blades are designed to include outstanding features, like an expansion slot and other features that result in optimized cutting quality and superior operations. The 303mm HW saw blade by LEUCO is engineered for plastic materials, and is compatible with table saws and vertical panel saws. This product serves the industrial and craft sectors, catering to the growing use of plastics in the furniture industry, among other industries that you may serve.

Highline Tungsten Carbide Specialty Cutting G5 Saw Blade for Thin Plastics

LEUCO’s Highline Tungsten Carbide Specialty Cutting G5 Saw Blade for Thin Plastics provides the highest quality when sawing thin polycarbonate panels, twin-wall sheets, for instance. Lightweight and brittle panels of extruded polystyrene can also be processed very well with this saw blade.

This specialty saw blade is also designed for cutting hard and abrasive thermosets. Thus, high-pressure laminates (HPL) can be sawed quickly and with high quality with this blade. Additionally, the G5 saw blade offers an excellent cutting quality in “anti fingerprint” materials and for conventional plastics. The convex tooth sides prevent the formation of grooves on the cutting surface and flares on the surface of sensible materials.

Plastics Processing Gallery

-

Sawing

The "Plastics" saw blade processes all transparent PMMA panels as well as transparent polystyrene panels (Wattolene). It also saws solid polycarbonate(PC) panels, available under names such as Lexan and Makrolon.

-

Drilling

The "Plastics" saw blade processes all transparent PMMA panels as well as transparent polystyrene panels (Wattolene). It also saws solid polycarbonate(PC) panels, available under names such as Lexan and Makrolon.

-

Milling

LEUCO milling tools can be used in many ways. They are characterized by high machining quality and a long service life and can be used

for high-performance machining.