Page Title: Maridur 30-70 Material Cutting SolutionsMaridur 30-70 Material Cutting Solutions

Many industry professionals refer to Maridur 30-70 as "the interior and exterior material,” which speaks to its versatility and flexibility for manufacturers.

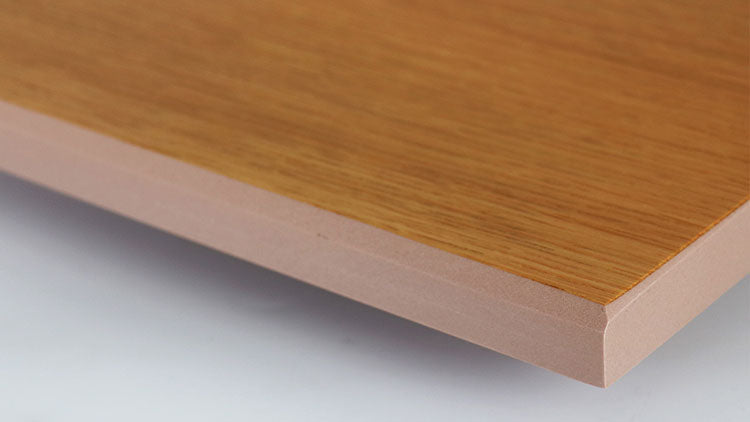

About Maridur 30-70

Maridur 30-70 is a high-performance engineering material known for its excellent dimensional stability and resistance to deformation under stress, making it a preferred choice in various manufacturing industries. Composed primarily of a densely packed synthetic resin, Maridur 30-70 is used primarily in applications where precision and durability are paramount.

Applications

Maridur 30-70 is easy to coat or paint, has a great structure, and is widely utilized in the creation of interior finishing products, lateral panels, front panels, door filling for front doors, profile ledges, handrails, insulating glass panes, inner ledges, cornices, skirting boards, ceiling claddings, and closing edges, though the possibilities extend to even more potential applications for experienced manufacturers.

Challenges

Despite its benefits, cutting Maridur 30-70 poses a significant challenge for manufacturers. The material's hardness and density require specialized tools and techniques to achieve clean, accurate cuts without causing defects such as chipping or cracking. Traditional machining processes can struggle to handle the demands imposed by Maridur 30-70, potentially leading to increased costs and broader inefficiencies in production.

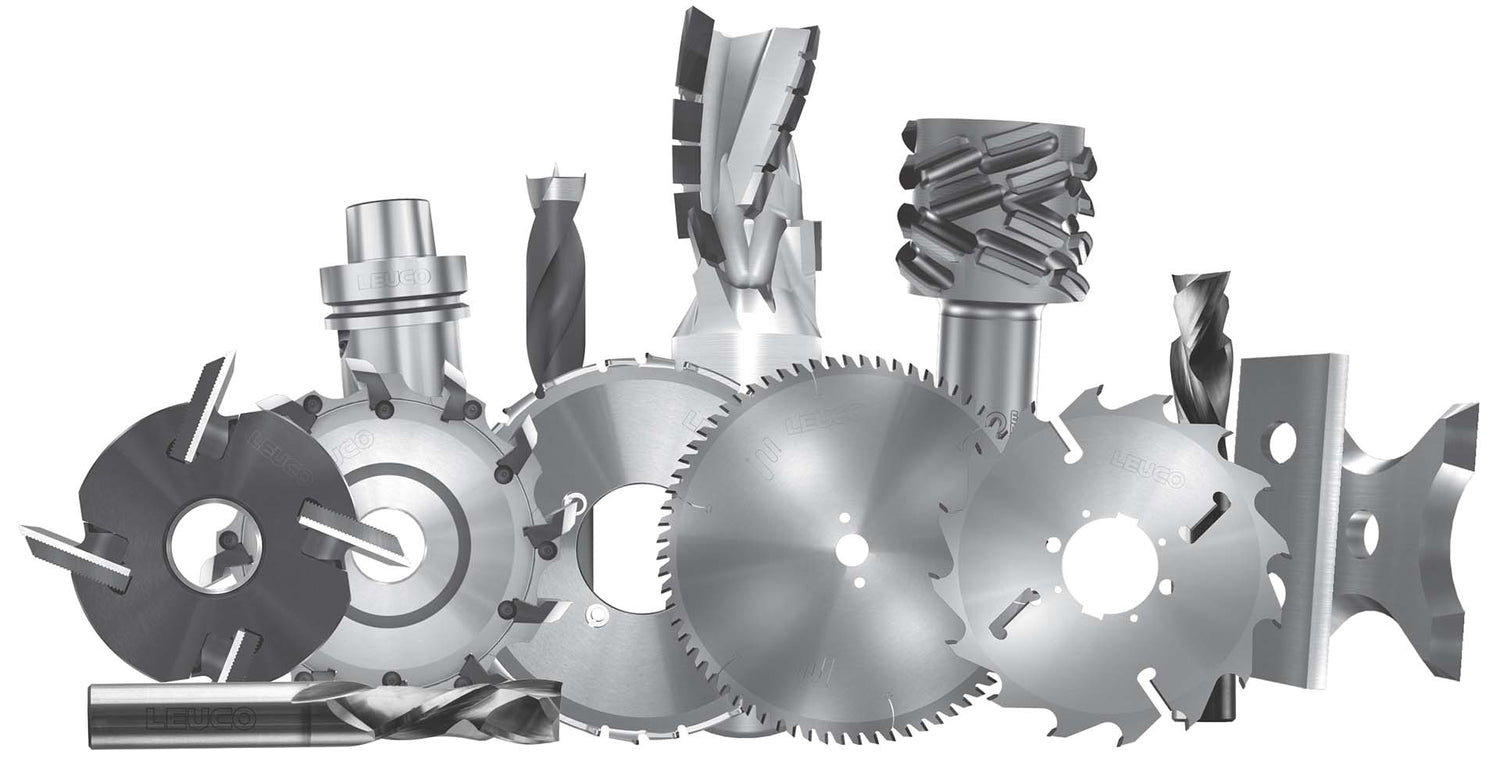

LEUCO provides world-class tooling solutions and expert support for machinery and processing of many materials.

Shop NowNobody Offers Solutions for Your Maridur 30-70 Material Processing Needs Like LEUCO

One of the few companies offering tailored solutions for processing Maridur materials is LEUCO. We stand out in the industry by providing cutting-edge tooling solutions specifically designed to handle the unique challenges presented by Maridur 30-70. LEUCO's advanced tool technology ensures precise cuts and extends tool life, reducing downtime and increasing productivity for manufacturers. Our dedication to innovation and quality has positioned us as a leader in the industrial tooling industry, offering unmatched expertise and support for businesses working with this complex material.