Page Title: Circular Saw Blade SolutionsCircular Saw Blade Solutions

Choosing LEUCO Means Choosing Quality, Sustainability, And Innovation. It Starts with Industry-Leading Circular Saw Blade Solutions and Ends with Your Success.

When it comes to ensuring the highest standards of precision, durability, and innovation in tooling, LEUCO stands unmatched. For over 40 years, we've been providing North America with top-tier precision tooling and re-sharpening services. LEUCO is a global leader in precision tooling solutions, setting industry standards with our commitment to innovation over imitation. Our circular saw blade solutions guarantee the highest quality and longest edge life, ensuring your operations run smoothly and cost-effectively for years to come.

LEUCO Definitions

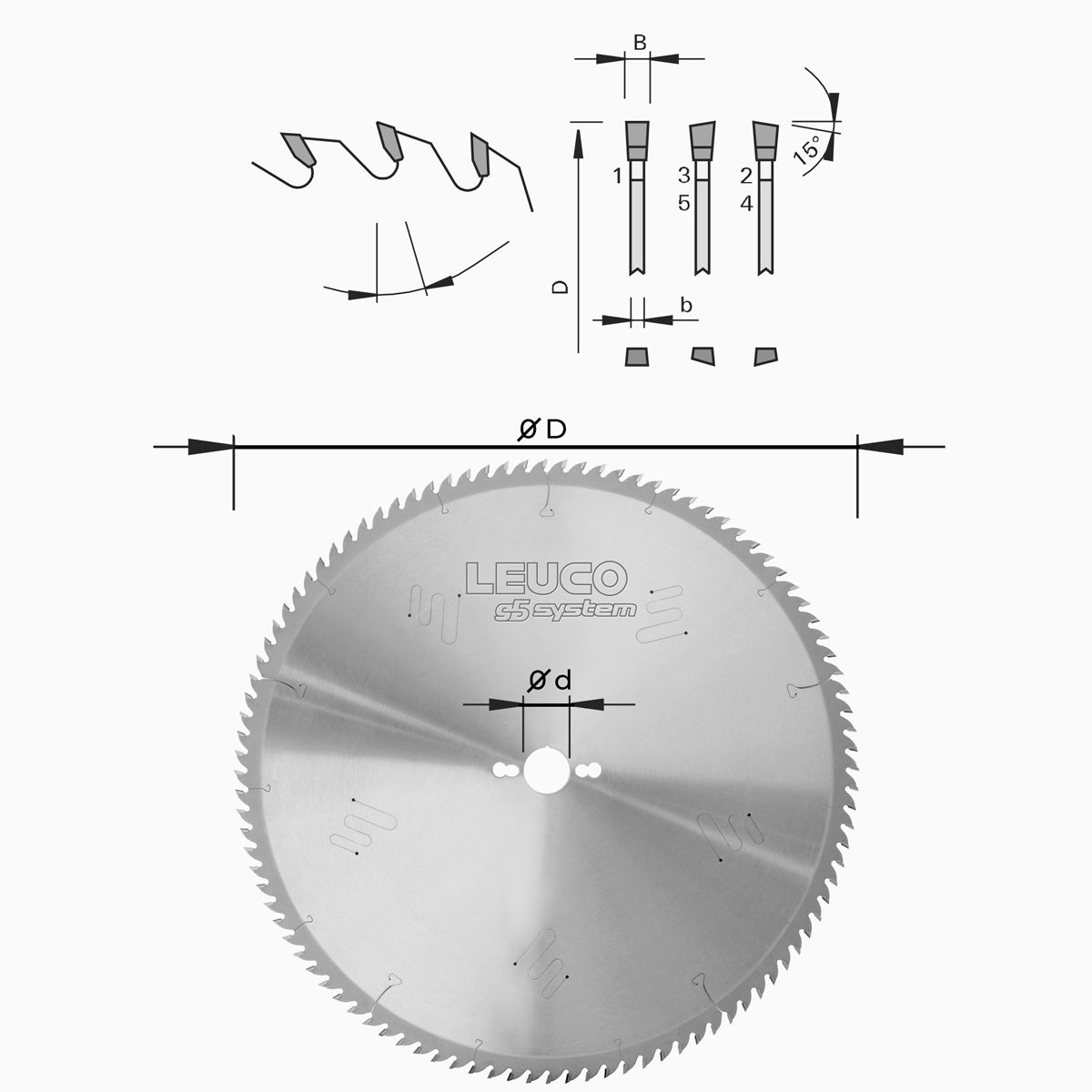

Circular Saw Blade Specifications

Blade body thickness is a critical factor influencing both weight and durability. A lighter base body reduces energy consumption per machine, but it must be balanced against the need for impact and warp resistance in demanding industrial applications. It's important to note that the blade body is always thinner than the teeth. This intentional design minimizes excessive friction and prevents rapid heat buildup during cutting. Maintaining uniform thickness would lead to burn marks and slow cutting due to increased friction.

By carefully selecting the appropriate thickness and considering the strategic design of a circular saw blade, professionals can significantly extend blade lifespan, minimize energy waste, and ensure efficient operation. With our commitment to quality and innovation, we lead the industry, delivering reliable solutions that exceed expectations.

Increasing the wear resistance of a blade often reduces their bending strength due to physical constraints. As the hardness of the blade steel increases, blades tend to become more brittle. Conversely, softer blade steel offers greater bending strength. These characteristics can be advantageous or disadvantageous depending on the specific application.

For instance, polycrystalline diamond, known for its exceptional hardness and wear resistance, is also one of the most brittle cutting materials, prone to breaking upon impact. On the opposite end, high-speed steel (HS) is among the softer cutting materials, offering better impact resistance but dulling quickly.

LEUCO has developed carbide-tipped saw blades using various combinations of cobalt and tungsten carbide steel (HW), broadening the range of applications. Consequently, LEUCO provides several grades of carbide-tipped saw blades:

- HL Solid 60 to 25 is ideal for softwoods like spruce, fir, pine, and alder.

- HL Solid 25 to HL Board 06 is suited for cutting particle boards, MDF, and hardwoods.

- HL Board 05 to 03 works well with wood-based panels, plastics, and hardwoods.

- HL Board 03 to 01 is best for highly abrasive materials like highly compressed or cement-bound particle boards.

Circular blade tooth design has a big influence on the edge quality and is dependent on the workpiece material, the mode of application, and the direction of cut. The grouping of the teeth affects the cutting of the blade and these factors determine the effectiveness of the many solutions we can provide.

- F: Flat

- F-FA: Flat with chamfers on both sides

- F-WFA: Flat with alternating chamfers

- WS: Alternate top bevel

- WS-FA: Alternate top bevel with chamfer

- TR: Triple-chip

- TR-F: Triple-chip flat

- TR-F-FA: Triple-chip flat with chamfer

- TR-TR: Triple-chip, plus Triple-chip

- DA: Inverted-V

- DA-F: Inverted-V flat

- DA-F-FA: Inverted-V flat with chamfer

- DA-D: Inverted-V hollow-ground

- DA-D-FA: Inverted-V hollow-ground with chamfer

- ES: Top Bevel

- ES-L: Top Bevel left

- ES-R: Top Bevel right

- KO-F: Conical-flat

- KO-WS: Conical-alternate bevel

- KO-HR-FA: Conical hollow-back with chamfer

- D: Hollow ground

- D-FA: Hollow-ground with two-sided chamfer

- HR: Hollow-back

- HR-FA: Hollow-back with chamfer

- G3: 3-tooth combination in specified numbered sequence

- G5: 5-tooth combination in specified numbered sequence

- G6: 6-tooth combination in specified numbered sequence

Circular Saw Blade Specifications

Cutting-edge materials significantly enhance edge life and cutting quality. The concept of the "ideal cutting material" demands equal parts bending strength and wear resistance. Despite intensive research, this remains an aspirational goal. However, selecting the appropriate cutting material based on specific requirements—such as cutting quality, cost-efficiency, and machine downtime—is achievable. LEUCO stands as a leader in this field, offering not only tools but an extensive range of cutting materials tailored for diverse applications.

Among the most popular cutting edge materials for circular saw blades are Carbide Tipped and Diamond Tipped, epitomizing our commitment to quality and innovation.

- Carbide Tipped: Sawblades with tungsten carbide tipped teeth are essential in woodworking, known for their durability and performance. Made with tough tungsten carbide, these TCT tips provide a strong, resilient edge. Known for lasting sharpness, even with tough materials, carbide-tipped sawblades offer reliability and precision. Our carbide-tipped sawblades ensure quality and innovation, inspiring confidence and exceeding expectations in any woodworking application.

- Diamond Tipped (DP): Polycrystalline Diamond (DP) tipped sawblades are designed for precision in cutting tough materials. Made from bonded diamond particles, DP offers unmatched durability and wear resistance. These blades are ideal for cutting abrasive surfaces like laminates, chipboard, melamine, composites, and materials such as cement fiberboard and certain plastics. The diamond-tipped cutting edges are treated with the special LEUCO "topcoat" coating. The coating on the tooth flanks helps to keep dirt from sticking to the blades, thus extending the edge lives of the diamond tips by up to 50 %. LEUCO DP sawblades showcase our brand's dedication to innovation and quality, establishing us as industry leaders. With expertise, we provide solutions that meet and exceed expectations, ensuring reliability and trust in every cut.

Why Invest In Circular Saw Blade Solutions with LEUCO?

For the ultimate in precise, efficient, and sustainable cutting solutions, LEUCO circular saw blades stand out in the market. Here’s just a few of the reasons why we are the preferred choice for woodworking professionals, plastics manufacturers, industrial tool makers, sawmill operators, furniture manufacturers, paneling industry professionals, building material manufacturers, folks in the interior finishing industry, and many other hard-working professionals.

You Value Innovative, High-Quality Materials

LEUCO utilizes cutting-edge materials that extend the life of our blades beyond what is typical in the industry. This means less frequent replacements and more consistent performance over time, saving you money and hassle, all while improving your quality and efficiency.

You Value Advanced Tooth Designs

Our circular saw blades boast state-of-the-art tooth designs that significantly reduce noise, enhance cutting accuracy, and minimize material waste. This leads to a quieter work environment and a more efficient use of resources.

You Value Customizable Options

With a variety of customizable blade options, LEUCO ensures a perfect fit for any manufacturing application you might have. Whether you’re dealing with wood, abrasive plastics, composite boards, various metals, or other materials, our blades offer the precision and efficiency you need.

You Value Eco-Friendly Manufacturing

LEUCO is committed to long-term sustainability for all of us. Our eco-friendly manufacturing processes not only reduce environmental impact but also meet the growing demand for responsible production practices. Using our blades means aligning with eco-conscious values.

You Value Competitive Advantages in Your Market

LEUCO blades provide superior cutting performance and longevity, thanks to our high-quality materials and innovative design features. This positions us as a top choice over other brands, offering unmatched value and reliability. LEUCO's tooling systems are designed to add tangible value to your operations. With our tools, you can achieve the lowest applied cutting cost, enhancing both your productivity and profitability.

You Value Specialized Product Range

The LEUCO DIAREX series, Practical G5 Blade, Panel Sizing Blades, and NN-System (No Noise System) DP flex circular saw blades are just a few of the exemplary products from LEUCO. These blades boast exceptional durability and cutting performance across varied applications. With features like diamond-tipped edges and topcoat layers, these blades maintain sharpness and reduce maintenance time, making them a smart investment. Explore our site for even more cutting-edge circular saw blade solutions!

You Value Expert Support and Services

Our world-class customer support network is backed by decades of expertise. We offer not just tools but also an array of services, including sharpening, application consulting, and complete tool management packages. We even extend our sharpening services to tools we didn’t manufacture, making us a comprehensive partner for your tooling needs.

Industry-Leading Circular Saw Blade Solutions from LEUCO – Our Expertise is Only the Beginning

While it’s great to get unmatched quality and innovation, and value-added tooling systems, you have the opportunity to join a community of like-minded professionals who trust LEUCO for all their cutting needs. From sawmills to interior finishing industries, our reputation among industry leaders is a testament to our commitment to quality and service.

Choosing LEUCO means choosing reliability, expertise, and a partner dedicated to your success. Whether you're a professional woodworker or an industrial manufacturer, our circular saw blades deliver the precision and efficiency you need to stay ahead. Experience the difference with LEUCO's precision tooling solutions and elevate your operations today!